Bugao Xu Ph.D.

Merchandising and Digital Retailing

Professor

About

Biography

Dr. Bugao Xu received his Ph. D. from the University of Maryland at College Park in August 1992, and started his career at the University of Texas at Austin as an Assistant Professor in January 1993. After 23 years of service at UT Austin, he joined the faculty of the University of North Texas (UNT) in 2016. Currently, he is a professor in the Department of Merchandising and Digital Retailing of UNT. His investigative research was focused on digital modeling and characterization of textile materials, 3D body imaging, virtual clothing, apparel fit and customization, made-to-measure technology, and AI in retail. He is also interested in cross-disciplinary research, such as obesity assessment and automated pavement inspection. He has authored over 220 refereed journal papers (>170 in SCI/SSCI journals) and more than 90 peer-reviewed conference proceedings. As a PI, he received a total of $5.3 million grants from NSF, USDA, NIH, Texas Higher Education Coordinating Board, Texas Food and Fiber Commission, Texas Department of Transportation, Cotton Inc., Walmart Foundation, VF and other private businesses. He also provided consultative or cooperative work on digital textiles to many companies such as P&G, Unilever, J&J, Maytag, and Cotton, Inc.

Research Projects

3D Microscopy for High-throughput Phenotyping of Cotton Fibers

This project is focused on developing improved methods to assess phenotypic traits of cotton, with the ultimate goal of improving cotton fiber quality. Existing techniques to phenotype cotton fibers have a range of limitations, including inaccuracy, laborious sample preparation, and low throughput analysis. To address these challenges, our project aims to pioneer a new, high-throughput methodology for fiber phenotyping, encompassing both sample preparation and analysis. This will involve the development of robust models using deep learning algorithms to generate 3D surface representations of fibers for accurate fineness and maturity measurements. Additionally, we plan to utilize cotton diversity panels to calibrate and validate our results.

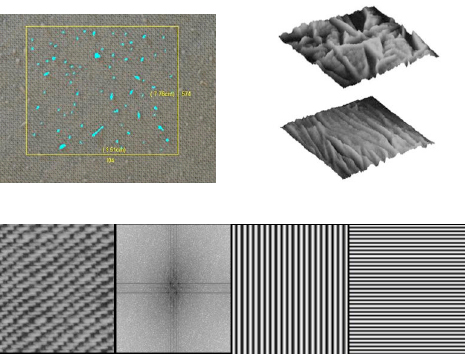

On-Loom Fabric Defect Inspection Using Contact Image Sensor and Machine Learning

This proposed project aims to develop an on-loom fabric inspection system that is reliable, practical, and cost-effective, utilizing contact image sensors (CIS) and advanced defect detection algorithms. Unlike traditional camera systems, which require separate lighting and stand at a distance, a CIS unit integrates the sensor chip, signal amplifier, and LED lights on the same substrate. This compact and lightweight design, along with an extremely short focal length, makes CIS particularly suitable for on-loom inspection where space, resolution, and cost are critical factors for success. Upon completion, the system will demonstrate early detection of defects, compact size without obstructing the weaver’s view, sub-millimeter resolution, and robust AI models for consistent defect detection.

Web mining system for retail analytics

We used big-data technology to create a scalable system that can fetch webpage contents of an online retailer, including customers’ reviews, ratings, demographic data and product information. The system can access and process not only HTML/CSS documents but also dynamic scripts and other resources in real-time. The downloaded contents can be used customer segmentation to enhance marketing strategy and customer loyalty programs. NLP techniques are used to construct deep-learning models to perform aspect-based sentiment analysis of user review texts for personalized product recommendations.

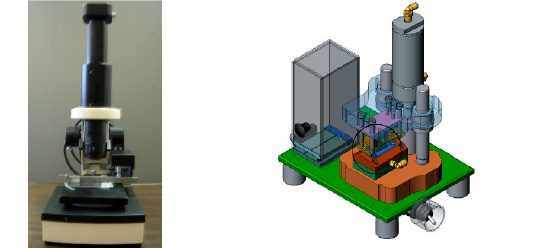

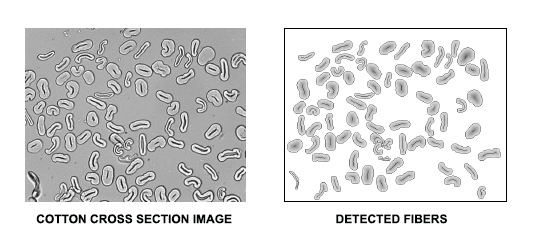

Fiber Image Analysis System--FIAS (US patent 7588438)

The FIAS is a customized microscopic image analysis system for automatic, high-volume measurements of fiber geometric attributes. The major components of the FIAS include a zoomable microscope, a high resolution camera, a motorized stage, a pneumatic fiber cutter/spreader, and image analysis software. FIAS offers two basic functions: longitudinal analysis and cross-sectional analysis of fibers.

The longitudinal analysis scans a fiber transversely along its axis, and provides the measurements of fiber diameter/width, diameter distribution, blend ratio of two different fibers, cotton maturity, cotton dead fiber ratio, etc. Prior to the analysis, fibers are cut into 0.5mm snippets, and spread onto a microscope slide using the pneumatic fiber cutter/spreader. The fiber snippets on the slide are consecutively imaged and measured as the slide is automatically shifted by the motorized stage. Proprietary computer algorithms include fiber axis calculation, double transverse scans, false scan prevention, dead fiber detection, and cotton maturity calculation. It is expected to measure up to 50,000 fiber scans per slide, which are sufficient for reliable statistic analysis.

The cross-sectional analysis provides feature measurements including fiber perimeter, area, equivalent diameter, and shape factors (circularity). For hollow fibers, such as cotton and medullated animal fibers, the wall thickness, maturity or medullation can be measured. For multi-lobal fibers, such as trilobal nylon fibers, the modification ratio can be measured.

FIAS (left) and Fiber Cutter/Spreader (right)

Imaging Colorimeter for Cotton Trash and Color Measurement

A new system that automatically captures images of raw cotton, locates non-lint particles in the image, and uses fuzzy logic and neural network methods to classify cotton colors and trash particles. The system considerably improves the agreements with the human classer. It can perform multiple functions: 1) trash content and grading; 2) trash category (leaf, bark and seedcoat); 3) content of yellow spot; 4) color data in various color spaces (Rdab, CIE L*a*b* or CIE L*c*h*) and color grading.

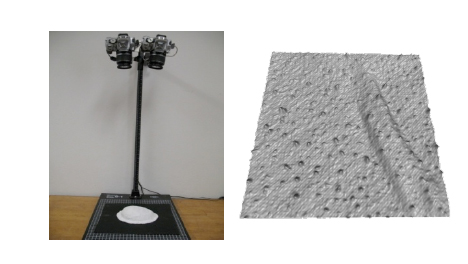

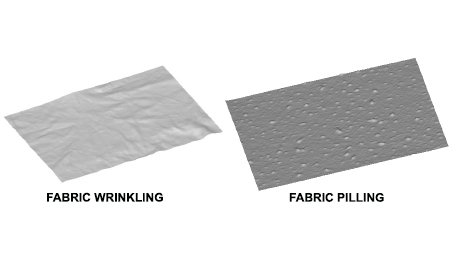

Objective Evaluation of Fabric Appearance

A “single hardware setup” solution was developed for multiple functions of objectively characterizing and evaluating surface changes of fabrics such as wrinkling, fuzzing, pilling and shrinking. The ratings of these surface features were trained using the standard replicas (AATCC and ASTM) or physical samples representing different scales set visually by experts. The system has greatly improved the objectivity of fabric appearance evaluations, and reduced the cost and the time for performing multiple tests.

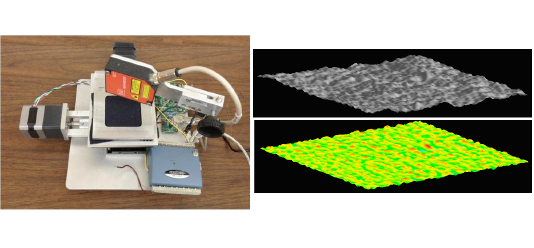

Laser Profilometer for Surface Wear Assessment

The project was to measure surface characteristics (profile, roughness, fuzziness, etc.) of a wide range of materials such as fabric, plastic and metal. The system consists of a laser displacement sensor (4-um depth resolution), motorized x-y mechanical stage (70x70 mm2 travel), and customized software.

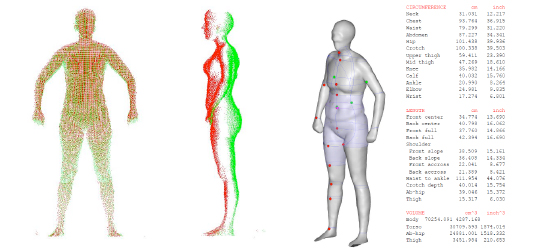

Three-Dimensional Body Imaging

For the past ten years, Dr. Bugao Xu and his “Human Dimension Research” team has been working on developing three dedicated 3D systems for fast and accurate generations of high-fidelity surface images.

(1) Rotary laser scanner

The rotary scanning unit mainly comprises a laser sensing unit and a step motor, which are installed on the top of a tripod. The computer then traces the line in each image and calculates the 3D coordinates of all the pixels on the line. The coordinates from the frontal and rear images are registered together to form a full body surface according to the relative positions of the two scanning units. A total of 250 to 350 images are captured and processed within 2-3 seconds, depending on the height of the subject. The rotary scanning makes the unit much more compact, lighter and thus more portable. Each unit weighs less than 2.5 kilograms, and the entire setup takes a footprint of 1.5m by 2.4m.

(2) Kinect body imaging system (KBI)

KBI system is a 3D Body Imaging and measurement system. The KBI uses 4 Microsoft Kinect sensors to acquire 3D data clouds of front and back surfaces of a whole body. After the precise registration, the front and back views of the body can be merged and reconstructed to form a smooth and complete digital model that is scalable and rotatable on the computer screen. The digital model can be used for measurement extractions, custom clothing and virtual try-on. The KBI system provides both hardware and software for 3D body imaging, which is quick (< 1s imaging time), portable (on stands), compact (2m x 1.5m footprint), economical and accurate (~1mm). It has a viewing volume of 2m x 1m x 0.8m (Height x Width x Depth). The body measurements include many circumference, length and volume data at pre-defined landmarks, and can be taken manually with “e-tape” tools.

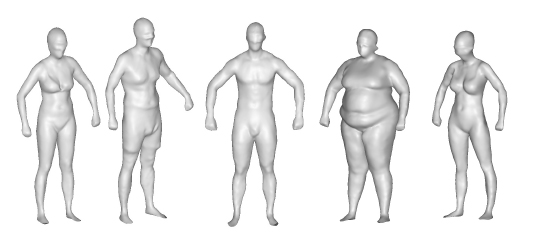

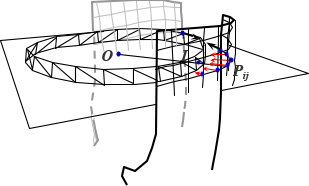

(3) Stereovision body imaging system (SBI)

Stereovision Body Imaging (SBI) system uses 4 high-resolution digital cameras to take front and back images of a body, and a multi-resolution stereo-matching algorithm to generate 3D data clouds of the surface. After the precise registration, the front and back views of the body can be merged and reconstructed using the subdivision modeling algorithm to form a smooth and complete digital model that is scalable and rotatable on the computer screen. The SBI system solution for 3D body imaging is quick (0.2 s imaging time), portable (on stands), easy to calibrate, economical and accurate (<1mm). The scanned body images and their measurements can be stored in a database for later secure access. Possible applications include: obesity, body shape analysis and weight management, apparel fit and sizing system, and ergonomic products.

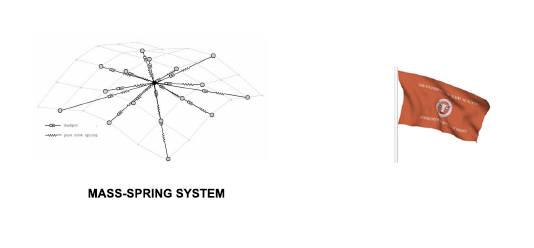

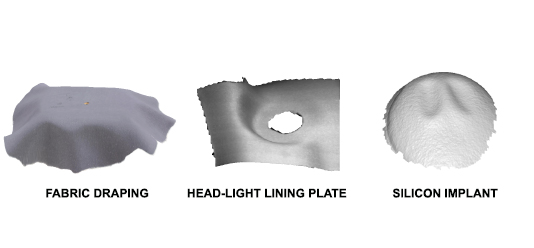

Virtual Clothing

The garment dressing simulation conducts a transformation of multiple 2D garment patterns into a 3D configuration that follows the surface of a human body, and displays the draping style of the garment. During this transformation, the dimensional stability of the garment patterns is an important constraint that needs to be imposed to ensure the created garment to have a size complied with the original design of the patterns. The four issues are fabric modeling, mesh generation, wrapping and draping.

Fabric modeling is a way to simulate fabric properties using a simple mechanic system. This is an important step for obtaining realistic visualization of a 3D garment. I A mass-spring system constitutes a matrix of mass particles, representing the distributed mass of the fabric, and three types of springs connecting the particles and representing three different internal forces: tensile, shearing and bending. A mass-spring system with reasonable combination of the stiffness and viscosity of the spring can develop a cloth-like deformational behavior.

Mesh generation is a process to automatically setup the distributions and connections of particles and springs on a given garment pattern, which may have irregular shapes. In our approach, this procedure is carried out in two steps: the first step is to generate the nodes for the given pattern that represent the mass distribution of the mass-spring system, and the second step is to generate a list of triangles in terms of Delaunay triangulation.

Wrapping is the 2D-3D transformation that merges the particles on the sewing edges of a pattern with those of the matching pattern, and moves the inner particles of all the sewn patterns towards the body surface. The stiffness coefficients of the tensile and shearing springs can be set purposely to a value much higher than their empirical values. In the wrapping, the gravity, friction, air resistance and other external forces are not considered, and the sewing forces are formed by an adaptive force field distributed on each particle. In each iteration of computing the displacements of the particles, the collisions between the particles and the body surface are detected to prevent surface penetrations. The wrapping ends when all the sewing edges are merged. Wrapping creates an initial status for draping.

Draping is the further pattern transformation to produce the draping effects by using realistic spring values in the fabric model, and adding all the external forces. Collision detection, and strain control and size stability are the major issues in the draping simulation.

Stereovision System for 3D imaging and Measurement

The prototype of a stereo vision system includes two CMOS digital cameras and a DPL digital projector. A random noise pattern is projected onto the object surface, and two digital images are acquired with one snapshot. We have implemented various effective stereo matching algorithms which can infer reliable disparities with sub-pixel accuracy, and the 3D modeling algorithms which can smoothen and simplify the raw data while keeping enough details.

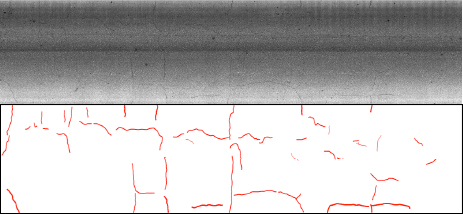

High-Speed, Real-Time Highway Pavement Distress Inspection (US patent 7697727)

The system, equipped with a line-scan camera and a high-speed frame grabber, is installed in a designated vehicle, and can take up to 44,000 lines or 88 meters pavement surface images per second while it covers full pavement lane (3.66 meters). A multiresolution segmentation algorithm for crack detection was developed to meet the high-speed requirement. The algorithm takes less than 20 milliseconds as running on a 2 GHz Pentium IV processor and can reliably detect a variety of cracking distresses. The system is able to conduct the survey at a vehicle speed from 5 to 112 kmh-1, and report the cracking data in the ASSHTO, ASTM and PMIS formats and output a crackmap for the survey pavement. No human interference is required during the entire survey operation. The inspection data from the system have much better repeatability than those from the visual inspections.

A survey vehicle

A 60-feet pavement section (top) and the crackmap (bottom)

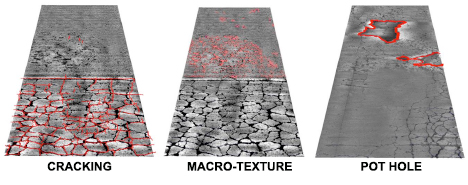

3D Pavement Scanning System

We developed an automated pavement inspection system using a 3D camera and a structured laser light to acquire dense transverse profiles of a pavement lane surface when it is carried by a moving vehicle. After the calibration, the 3D system can yield a depth resolution of 0.5 mm and a transverse resolution of 1.5 mm/pixel at the 1.4 m camera height from the ground. The scanning rate of the camera can be set to its maximum at 5000 lines/sec, allowing the density of scanned profiles to vary with the vehicle’s speed. The paper then illustrates the algorithms that utilize 3D information to detect pavement distresses, such as transverse, longitudinal and alligator cracking, and presents the field tests on the system’s repeatability when used to scan a sample pavement in multiple runs at the same vehicle speed, at different vehicle speeds and under different weather conditions. The results show that this dedicated 3D system can capture accurate pavement images that detail surface distress, and obtain consistent crack measurements in repeated tests and under different driving and lighting conditions.

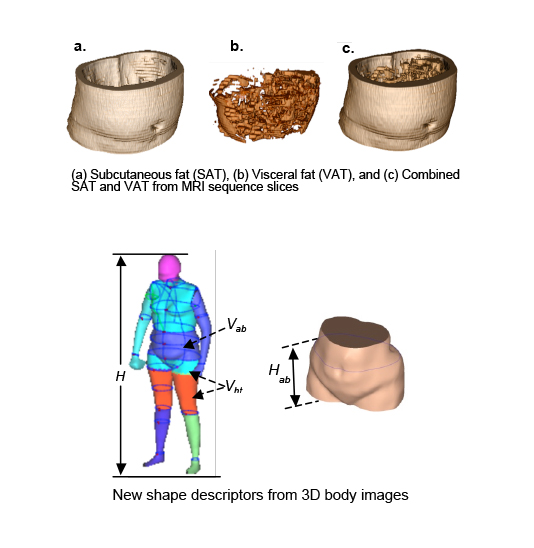

3D imaging system to investigate associations between body shape and obesity

Currently, 33.6% adults are overweight and 34.9% are obese in the United States1. Excess body fat is a public health concern due to its association with diabetes mellitus type 2 and other diseases. It is not only the amount of fat, but also its distribution in the body that is related to disease risks2–4. A meta-analysis by the authors found that diabetic/pre-diabetic populations have a great degree of visceral (abdominal) adiposity as compared to non-diabetic populations5. Thus, visceral adiposity (central obesity) as opposed to subcutaneous depots has greater implications in terms of diabetic risk. A new form of 3D imaging (stereovision) has enabled us to create more accurate, consistent and comprehensive body measures6. We have developed image-processing algorithms for unsupervised assessment of visceral and subcutaneous adipose tissue volumes from MRI abdominal images (Fig. 1), designed novel body shape descriptors to characterize overall and central obesity using 3D images from stereovision, and investigated the associations between internal adiposity data (MRI) and external body shape measurements (3D images). The new approach permits a more cost-effective and accurate obesity assessment for public health research.

Grant

- 3D Microscopy for High-throughput Phenotyping of Cotton Fibers, $294,000, USDA-NIFA- 2024-67013-41942, 3/1/2024-2/28/2027. PI.

- Enhancing Phenotypic Feature Extraction of Cotton Fibers through AI-based Image Fusion, $10,000, UNT Research Seed Grant, 2/1/2024-12/31/2024, PI.

- On-Loom Fabric Defect Inspection Using Contact Image Sensors, $345,198, Walmart U.S. Manufacturing Innovation Fund, 6/1/2016-12/31/2021, PI.

- Detection of Plastic Contaminants in Cotton Ginning Process Using NIR Optoelectronic Technology, $40,000, Cotton Incorporated, 1/1/2019-12/31/2019, PI.

- Dual-beard Fibrography for Cotton Length Distribution Measurement, $104,346, Cotton Incorporated, 7/1/2017-12/31/2020, PI.

- Body Imaging and Modeling, $60,000, Allcustom Tech Co., 12/04/2014-present, PI.

- Detection of Cotton Contaminants via Millimeter-Wave and Dual-Energy X-Ray Imaging, $57,974, Cotton Incorporated, 1/1/2016-12/31/2016, PI.

- Enhancing Fiber Cross-section Measurements to Eliminate Bias in the Cotton Maturity Reference, $168,442, Cotton Incorporated, 1/1/2013-12/31/2014, PI.

- A Portable Stereo Vision System for Whole Body Surface Imaging, $35,000, Office of Technology Commercialization, University of Texas at Austin, 9/1/2009-8/31/2011, PI.

- Validation and Evaluation of a Portable Body Scanner for Determination of Obesity, $715,512, National Institute of Diabetes, Digestive and Kidney Diseases, NIH, 10/1/2007-9/30/2010, PIs: J. Freeland-Graves and B. Xu.

- Support for Automated Visual Pavement Distress Measurement Systems, $620,000, Texas Department of Transportation, 9/1/2005-8/31/2009, PI.

- Improving Capabilities of Automated Distress Rating System, $296,544, Texas Department of Transportation, 9/1/2006-8/31/2008, PI.

- Artificial Light for Automated Pavement Distress Rating System, $500,000, Texas Department of Transportation, 2/1/2003-8/31/2007, PI.

- 3D Imaging, Modeling and Analysis of Breast in Reconstructive Surgery, $28,500, Center for Biomedical Engineering Research, 1/1/2006-12/31/2006. (Co-PI: Dr. Michael J. Miller, UT M.D. Anderson Cancer Center)

- Customized Microscopic System for High-Volume Measurement of Cotton Maturity, $97,000, USDA, National Research Initiative Competitive Grants Program, 11/15/2002-11/14/2006, PI.

- Implementation of Automated Pavement Distress Rating System, $744,000, Texas Department of Transportation, 9/1/2003-8/31/2005, PI.

- Development of Imaging System for Measurement of Cotton Fineness and Maturity, $104,000, Texas Food and Fiber Commission, 9/1/1999-8/31/2005, PI.

- Automated Pavement Surface Distress Rating System for Asphaltic Pavements, $626,000, Texas Department of Transportation, 6/23/1999~8/31/2003, PI.

- Development of Computer Vision System for Cotton Trash and Color Measurement, $420,087, Cotton Inc. and Texas Higher Education Coordinating Board, 1/1/1995-12/31/1999, PI.

- An Image Analysis System for Comprehensive Measurement of Natural Fibers, $139,850, National Science Foundation, 1995-1998, PI.

- Characterization of Natural Fibers by Image Analysis, $86,474, USDA, National Research Initiative Competitive Grants Program Award, 1995-1998, PI.

Publications

Papers Published in SCI/SSCI Journals (*Corresponding author; +Supervised student, visiting scholar or postdoc researcher.)

- Kim, H.J.*, Delhom, C.D., Jones, D.C. and Xu, B., Comparative analyses of AFIS distributional parameters evaluating immature fiber contents within cotton materials, Journal of The Textile Institute, Online First, 4/25/2023. https://doi.org/10.1080/00405000.2023.2204460 (IF=1.770)

- Zhou, J.+ and Xu, B.*, Predicting Cotton Fiber Properties with Fiber Length Parameters Measured by Dual-beard Fibrograph, Cellulose, 30(3), 2053–2065, 2023. https://doi.org/10.1007/s10570-022-05017-3 (IF=6.123)

- Zhan, Z.+ and Xu, B.*, Analyzing Review Sentiments and Product Images by Parallel Deep Nets for Personalized Recommendation, Information Processing & Management, 60(1), Article 103166 (13pp), 2023. https://doi.org/10.1016/j.ipm.2022.103166 (IF=7.466)

- Zhan, Z.+, Zhou, J.+ and Xu, B.*, Fabric Defect Classification Using Prototypical Network of Few-Shot Learning Algorithm, Computers in Industry, 138(6), Article 103628, 2022. https://doi.org/10.1016/j.compind.2022.103628 (IF=11.245)

- Ma, Y.J., Zhao, X.H., Wang, L.+*, Xu, B., Pan, R.R.+ and Gao, W.D., Three-dimensional Measurement of Yarn Evenness Using Mirrored Images, Measurement, 191(3), Article 110834, 2022. https://doi.org/10.1016/j.measurement.2022.110834 (IF=5.131)

- Lyu, J.+, Cheng, L.*, Xu, B.* and Hua, Z., Numerical Simulation of Fiber Motion in the Condensing Zone of Lateral Compact Spinning with Pneumatic Groove, Autex Research Journal, 22(1), 35-41, 2022. https://doi.org/10.2478/aut-2021-0003 (IF=1.944)

- Yin, W.+ and Xu, B.*, Perceptual Evaluations of Plant-dyed and Industrial-dyed Cotton Fabrics Based on Kansei Engineering, AATCC Journal of Research, 9(1), 23–34, 2022. https://doi.org/10.1177/23305517211060793 (IF=1.127)

- Kim, H.J.*, Delhom, C.D., Liu, Y., Jones, D.C. and Xu, B., Characterizations of a Distributional Parameter That Evaluates Contents of Immature Fibers within and among Cotton Samples, Cellulose, 28(9), 9023–9038, 2021. https://doi.org/10.1007/s10570-021-04135-8 (IF=5.044)

- Yin, W.+ and Xu, B.*, Effects of Online-Shopping Experience on Customer Loyalty in Apparel Business-to-Consumer Ecommerce, Textile Research Journal, 91(23–24), 2882–2895, /2021. https://doi.org/10.1177/00405175211016559 (IF=1.820)

- Zhou, J.+, Wei, J.+ and Xu, B.*, Customer Segmentation by Web Content Mining, Journal of Retailing and Consumer Services, 61(7), Article 102588, 2021. https://doi.org/10.1016/j.jretconser.2021.102588 (SSCI, IF=7.135)

- Yao, L., Wan+*, Y., Ni, H. and Xu, B., Action Unit Classification for Facial Expression Recognition Using Active Learning and SVM, Multimedia Tools and Applications, 80(7), 24287–24301, 2021. https://doi.org/10.1007/s11042-021-10836-w (IF=2.757)

- Lang, C., Zhang, M., Wang, T., Jin, J.+*, Wang, F., Xu, B. and Qiu, Y., Image-based bilateral beard method for measuring weight-based short fiber contents in raw cotton and semi-finished sliver, Textile Research Journal, Online First, 2021. https://doi.org/10.1177/0040517521997465 (IF=1.820)

- Lyu, J.+, Cheng, L.*, Xu, B.*, Modeling Additional Twists of Yarn Spun by Lateral Compact Spinning with Pneumatic Groove, Computer Modeling in Engineering and Sciences, 127(2), 737-751, 2021. DOI:10.32604/cmes.2021.015153 (IF=0.805)

- Zhou, J.+ and Xu, B.*, Reliability of Cotton Length Distributions Measured by Dual-Beard Fibrography and Advanced Fiber Information System, Cellulose, 28(3), 1753–1767, 2021. DOI:10.1007/s10570-020-03611-x (IF=5.044)

- Sun, J.+, Xu, B.*, Lee, J. and Freeland-Graves, J., Classifying Abdominal Fat Distribution Patterns by Using Body Measurement Data, Computer Modeling in Engineering and Sciences, 126(3), 1189-1202, 2021. https://doi.org/10.32604/cmes.2021.014405. (IF=0.805)

- Li, W.Q.+ and Xu, B.*, Aspect-based Fashion Recommendation Model with Attention Mechanism, IEEE Access, 8(8), 141814–141823, 2020. https://doi.org/10.1109/ACCESS.2020.3013639 (IF=3.745)

- Zhou, J.+ and Xu, B.*, Evaluating Cotton Length Uniformity through Comprehensive Length Attributes Measured by Dual-Beard Fibrography, Cellulose, 27(13), 7861–7871, 2020. https://doi.org/10.1007/s10570-020-03326-z (IF=4.210)

- Yao, M.+, Ouyang, W.+ and Xu, B.*, Hybrid Cost Aggregation for Dense Stereo Matching, Multimedia Tools and Applications, 79(31), 23189–23202, 2020. https://doi.org/10.1007/s11042-020-09127-7 (IF=2.313)

- Lang, C., Wu, M., Pan, X., Jin, J.*+, Wang, F., Xu, B. and Qiu, Y., Algorithm for Measuring Fiber Length Distributions of Raw Cotton and Combed Wool Using Dual-beard Image Method, Textile Research Journal, 90(19), 2149–2160, 2020. https://doi.org/10.1177/0040517520913525 (IF=1.926)

- Zhang, W.+, Zaarour, B., Zhu, L., Huang, C., Xu, B., and Jin, X.*, A comparative study of electrospun polyvinylidene fluoride and poly(vinylidenefluoride-co-trifluoroethylene) fiber webs: mechanical properties, crystallinity, and piezoelectric properties, Journal of Engineered Fibers and Fabrics, 15(7), 1-8, 2020. https://doi.org/10.1177/1558925020939290 (IF=0.814)

- Hou, J.+, Ouyang, W.+, Xu, B. and Wang, R.*, Convolutional Neural Network for Point Clouds Extraction of Fibrous Web from Multi-focus Images, IEEE Access, 8(5), pp. 87857-87869, 2020. https://doi.org/10.1109/ACCESS.2020.2993625. (IF=3.745)

- Yao, M.+ and Xu, B.*, A Dense Stereovision System for 3D Body Imaging, IEEE Access, 7(12), 170907-170918, 2019. https://doi.org/10.1109/ACCESS.2019.2955915 (IF=3.745)

- Zhou, J.F.+, Wang, J.A.+, Wei, J.L.+, and Xu, B.*, Extracting Fiber Length Distributions from Dual-Beard Fibrograph with the Levenberg-Marquardt Algorithm, Textile Research Journal, 90(1), 37–48, 2020. https://doi.org/10.1177/0040517519858762 (IF=1.926)

- Wang, B.+, Xu, B.* and Li, H., Fabrication and Properties of C/C-carbon Foam Composites, Textile Research Journal, 89(21), 4452–4460, 2019. https://doi.org/10.1177/0040517519836942.(IF=1.926)

- Liu, Z.+, He, Q., Zou, F.Y. and Xu, B.*, Apparel Ease Distribution Analysis Using 3D Motion Capture, Textile Research Journal, 89(20), 4323–4335, 2019. https://doi.org/10.1177/0040517519832842 (IF=1.926)

- Xu, H.J.+, Xu, B.*, Jiang, Y.+, Balancing Apparel Assembly Line through Adaptive Ant-colony Optimization, Textile Research Journal, 89(18), 3677-3691, 2019. https://doi.org/10.1177/0040517518819836 (IF=1.926)

- Chen, J.+, Li, X. Wang, M., Ma, L. and Xu, B.*, Fast Compressive Tracking Combined with Kalman Filter, Multimedia Tools and Applications, 78(16), 22463-22477, 2019. https://doi.org/10.1007/s11042-019-7514-7 (IF=2.313)

- Ouyang, W.+, Xu, B.*, Hou, J.+ and Yuan, X.H., Fabric Defect Detection Using Activation Layer Embedded Convolutional Neural Network, IEEE Access, 7(6), 70130-70140, 2019. https://doi.org/10.1109/ACCESS.2019.2913620

- Su, J.Q.,+* Ke, Y., Kuang, C.Y., Gu, B.+ and Xu, B., Converting Lower-body Features from 3D Body Images into Rules for Individualized Pant Patterns, Textile Research Journal, 89(11), 2199-2208, 2019. https://doi.org/10.1177/0040517518790975

- Yu, L.J.+, Wang, G.L., Zhi, C., and Xu, B.*, 3D Web Reconstruction of Fibrous Filter Using Sequential Multi-focus Images, Computer Modeling in Engineering and Sciences, 119(2), 365-372, 2019. doi:10.32604/cmes.2019.04494

- Shi, M.*, Zhao, X., Qiao, D., Xu, B., and Li, C., Conformal Monogenic Phase Congruency Model-based Edge Detection in Color Images, Multimedia Tools and Applications, 78(8), 10701–10716, 2019. https://doi.org/10.1007/s11042-018-6617-x

- Ouyang, W.B.+, Xu, B.* and Yuan, X.H., Color Segmentation in Multicolor Images Using Node-Growing Self-Organizing Map, Color Research and Application, 44(2), 184-193, 2019. https://doi.org/10.1002/col.22333

- Wang, B.+*, Li, H., Xu, B. and Zhang, Y., Synthesis of Silica Microspheres on Silicon-modified Carbon Foams under Ablation, Materials and Manufacturing Processes, 34(4), 385-389, 2019. https://doi.org/10.1080/10426914.2018.1544715

- Fan, W.+, Tian, H., Wang, H., Zhang, T., Yang, X., Yu, Y., Meng, X., Yu, X., Yuan, L., Xu, B. and Wang, S.*, Enhanced Interfacial Adhesion of Aramid Fiber III Reinforced Epoxy Composites via Low-Temperature Plasma Treatment, Polymer Testing, 72(12), 147-156, 2018. https://doi.org/10.1016/j.polymertesting.2018.10.003

- Liu, C.+, Miao, F.X., Dong, X.Y. and Xu, B.*, Enhancing Pressure Comfort of Bra’s Under-band, Textile Research Journal, 88(19) 2250–2257, 2018. https://doi.org/10.1177/0040517517720496

- Hou, J.+, Xu, B., Gao, H.C. and Wang, R.W.*, Measuring Fiber Orientations in Nonwoven Web Images Through Bézier Fitting Contour, Textile Research Journal, 88(18), 2120–2131, 2018. https://doi.org/10.1177/0040517517716904

- Wang, J.A.+, Xu, B., Li, Z.J., Gao, W.D.* and Wang, L.+, Depth Recovery of Hairy Fibers for Precise Yarn Hairiness Measurement, Applied Optics, 57(24), 7021-7029, 2018. https://doi.org/10.1364/AO.57.007021

- Fan, W.+, Yuan, L.J., D’Souza*, N., Xu, B., Dang, W.S., Xue, L., Li, J., Tonoy, C. and Sun, R., Enhanced Mechanical and Radar Absorbing Properties of Carbon/Glass Fiber Hybrid Composites with Unique 3D Orthogonal Structure, Polymer Testing, 69(8), 71-79, 2018. https://doi.org/10.1016/j.polymertesting.2018.05.039

- Wang, L.+, Ouyang, W.+, Gao, W. and Xu, B.*, Multi-perspective Measurement of Yarn Hairiness Using Mirrored Images, Textile Research Journal, 88(6), 621–629, 2018. https://doi.org/10.1177/0040517516685281

- Wang, L.+, Xu, B.*, and Gao, W.D., 3D Measurement of Yarn Hairiness via Multi-perspective Images, Optical Engineering, 57(2), 025103 (9pp), 2018. https://doi.org/10.1117/1.OE.57.2.025103.

- Jin, J.+, Wang, F., and Xu, B.*, Measurement of Short Fiber Content with Dual-beard Image Method, Textile Research Journal, 88(1), 14-26, 2018. https://doi.org/10.1177/0040517516673333

- Zhou, J.F.+, Yu, L.J., Wang, R.W.* and Xu, B., Image Sharpness Enhancement for Textile Testing, AATCC Review, 18(2), 43-53, 2018.

- Pan, R.+, Gao, W., Xu, B.* and Li, W., Image Analysis for Seam Puckering Evaluation, Textile Research Journal, 87(20), 2513-2523, 2017. https://doi.org/10.1177/0040517516673330

- Hu, L., Wang, F.*, Xu, G.B., and Xu, B., Unique Microstructure of Kapok Fibers in Longitudinal Microscopic Images, Textile Research Journal, 87(18) 2255–2262, 2017. https://doi.org/10.1177/0040517516673334

- Zhou, J.F.+, Wang, R.W. and Xu, B.*, Fiber-Content Measurement of Wool-Cashmere Blends Using Near-Infrared Spectroscopy, Applied Spectroscopy, 71(10), 2367-2376, 2017. https://doi.org/10.1177/0003702817713480.

- Sun, J.J.+, Xu, B.*, Lee, J. and Freeland-Graves, J.H., Novel Body Shape Descriptors for Abdominal Adiposity Prediction Using Stereovision and MR Images, Obesity, 25(10),1795-1801,2017. https://doi.org/10.1002/oby.21957

- Liu, Z. +*, Zou, F., Zhan, Q. and Xu, B., Enhancing Thermal-Moisture Comfort of Lining Chest Wader for Fisherman, Textile Research Journal, 87(17), 2133–2145, 2017. https://doi.org/10.1177/0040517516665260

- Zhu, X.J.*, Wu, X., Shi, X. and Xu, B., Framework for Personalized Clothing Visualization, International Journal of Clothing Science and Technology, 29(3), 417-426, 2017. http://dx.doi.org/10.1108/ IJCST-07-2016-0080 (UNT)

- Bragança, S., Arezes, P., Carvalho, M.*, Ashdown, S., Xu, B., Castellucci, I., Validation Study of a Kinect-based Body Imaging System, Work, 57(1), 9-21, 2017. https://doi.org/10.3233/WOR-172532

- Wang, Q.D.+ and Xu, B.*, Coupled-contour Model for Effective Detection of Fiber Cross-sections in Wide-field Microscopic Images, Textile Research Journal, 87(12) 1509–1521, 2017. https://doi.org/10.1177/0040517516654113

- Chen, J.*, Sun, L., Negulescu, I. and Xu, B., Fabrication and Evaluation of Regenerated Cellulose/Nanoparticle Fibers from Lignocellulosic Biomass, Biomass & Bioenergy, 101(6), 1–8, 2017. https://doi.org/10.1016/j.biombioe.2017.03.024

- Gu, B.F.+, Su, J.Q.+, Liu, G.L.*, and Xu, B., Individualizing Women’s Suit Patterns Using Body Measurements from 2D Images, Textile Research Journal, 87(6) 669–681, 2017. https://doi.org/10.1177/0040517516636001

- Gu, B.F.+, Lin, W.P., Su, J.Q.+, and Xu, B.*, Predicting Distance Ease Distributions on Crotch Curves of Customized Female Pants, International Journal of Clothing Science and Technology, 29(1), 47-59, 2017. http://dx.doi.org/10.1108/IJCST-11-2015-0122

- Mo, H.F.+, Xu, B.*, Ouyang, W+. and Wang, J., Color Segmentation of Multi-color Fabrics Using SOM-based Clustering Algorithm, Textile Research Journal, 87(3), 369–380, 2017. https://doi.org/10.1177/0040517516631307

- Wang, L.+, Gao, W.D. and Xu, B.*, Objective Fuzziness Assessment of Multi-colored Fabrics Using High-resolution 3D Images, Journal of Testing and Evaluation, 45(5), 1485-1492, 2017. https://doi.org/10.1520/JTE20160301.

- Zhang, J., Pan, R.R.+*, Gao, W.D., Xu, B. and Li, W., Automatic Detection of Layout of Color Yarns of Yarn-Dyed Fabric Part 3: Multiple Double-System-Mélange Color Fabric, Color Research and Application, 42(2), 250–260, 2017. https://doi.org/10.1002/col.22068

- Wang, L.+ Ouyang,W+. Gao, W.D. and Xu, B.*, Instrumental Evaluation of Fabric Abrasive Wear Using 3D Surface Images, Journal of Textile Institute, 108(5), 846-851, 2017. https://doi.org/10.1080/00405000.2016.1193993

- Gu, B.F.+, Liu, G.L., and Xu, B.*, Girth Prediction of Young Female Body Using Orthogonal Silhouettes, Journal of Textile Institute, 108(1), 140-146, 2017. https://doi.org/10.1080/00405000.2016.1160756

- Sun, J.J.+, Xu, B.* and Freeland-Graves, J.H., Automated Quantification of Abdominal Adiposity by Magnetic Resonance Imaging, American Journal of Human Biology, 28(6), 757-766, 2016. https://doi.org/10.1002/ajhb.22862

- Zhang, J., Pan, R.R.+*, Gao, W.D., Xu, B. and Li, W., Automatic Detection of Layout of Color Yarns of Yarn-Dyed Fabric Part 2: Region Segmentation of Double-System-Mélange Color Fabric, Color Research and Application, 41(6), 626–635, 2016. https://doi.org/10.1002/col.22003

- Yu, L.J., Wang, R.W.*, and Xu, B., Rapid Acquisition of High-Volume Microscopic Images Using Predicted Focal Plane, Journal of Microscopy, 263(3), 320–327, 2016. https://doi.org/10.1111/jmi.12402

- Wang, R.W.* and Xu, B., Multi-focus Image Fusion for Accurate Measurement of Nonwoven Structures, Journal of Industrial Textiles, 46(3), 968-985, 2016. https://doi.org/10.1177/1528083715610295

- Yang, Z., Wang, F.* and Xu, B., Key Factors Affecting Binding Tightness between Two Components of PTT/PET Side-by-Side Filaments, Industria Textila, 67(4), 226–232, 2016.

- Chen, J.G.+*, He, S., Ma, L. and Xu, B., GM-PHD Filter with State-Dependent Clutters, Asian Journal of Control, 18(6), 1-7, 2016.https://doi.org/10.1002/asjc.1297

- Pan, R.R.+*, Zhang, J., Li, Z.J., Gao, W.D., Xu, B. and Li, W., Applying Image Analysis to Automatic Density Measurement of High-Tightness Woven Fabrics, Fibres & Textiles in Eastern Europe, 24(2), 66-72, 2016.

- Wang, L.+, Jiang, S.G., Liu, J.L., Pan, R.R.+, Gao, W.D.* and Xu, B., Validating Dynamic Testing of Fabric Crease Recovery with the Standard AATCC Testing Method, AATCC Review,16(4), 45-51, 2016.

- Wang, M., Li, X., Li, J.* and Xu, B., A New Approach to Quantify the Thermal Shrinkage of Fire Protective Clothing after Flash Fire Exposure, Textile Research Journal, 86(6), 580-592, 2016. https://doi.org/10.1177/0040517515595028

- Gu, B.F.+, Su, J.Q.+, Liu, G.* and Xu, B., Pattern Alteration of Women’s Suits Based on Ease Distribution, International Journal of Clothing Science and Technology, 28(2), 201-215, 2016. https://doi.org/10.1108/IJCST-07-2015-0083

- Su, J.Q.+, Liu, G.L.* and Xu, B., Development of Individualized Prototype Based on Classification of Body Features, International Journal of Clothing Science and Technology, 27(6), 895–907, 2015. https://doi.org/10.1108/IJCST-11-2014-0136

- Lee, J., Freeland-Graves, J.H.*, Pepper, R., Stanforth, P. and Xu, B., Prediction of Android and Gynoid Body Adiposity via a Three-dimensional Stereovision Body Imaging System and Dual-energy X-ray Absorptiometry, Journal of the American College of Nutrition, 34(5), 367–377, 2015. http://dx.doi.org/10.1080/07315724.2014.966396

- Chen, J.G.+, Xu, B.*, Ma, L. and Sun, R., GM-PHD Filter Combined with Track-estimate Association and Numerical Interpolation, Mathematical Problems in Engineering, Vol 2015, Article ID 629023 (9pp), 2015. http://dx.doi.org/10.1155/2015/629023

- Lee, J., Freeland-Graves, J.H.*, Pepper, R., Yu, W.+ and Xu, B., Efficacy of Thigh Volume Ratios Assessed via Stereovision Body Imaging as A Predictor of Visceral Adiposity Measured by Magnetic Resonance Imaging, American Journal of Human Biology, 27(4), 445–457, 2015. https://doi.org/10.1002/ajhb.22663

- Chen, J.G.+, Wang, N., Ma, L.L. and Xu, B.*, Extended-Target Probability Hypothesis Density Filter Based on Cubature Kalman Filter, IET Radar, Sonar & Navigation, 9(3), 324–332, 2015. https://doi.org/10.1049/iet-rsn.2014.0093

- Yao, M+., Zhao, Z.+, Yao, X.+ and Xu, B.*, Fusing Complementary Images for Pavement Cracking Measurement, Measurement Science and Technology, 26(2), 025005 (13pp), 2015. https://doi.org/10.1088/0957-0233/26/2/025005

- Su, J.Q.+, Gu, B. F.+, Liu, G.L.* and Xu, B., Determination and Application of Distance Ease of Pants Using 3D Scanning Data, International Journal of Clothing Science and Technology, 27(1), 47-59, 2015. https://doi.org/10.1108/IJCST-08-2013-0096

- Jiang, Y.+, Xu, B.* and Wang, S.Y., Entropy and Bulk of Yarns, Journal of Textile Institute, 106(2), 141-145, 2015. https://doi.org/10.1080/00405000.2014.906101

- Wang, R.*, Zhou, J.F. and Xu, B., Fusing Multi-focus Images for Yarn Hairiness Measurements, Optical Engineering, 53(12), 123101(7pp), 2014. https://doi.org/10.1117/1.OE.53.12.123101

- Yan, J.+, Wang, F. and Xu, B.*, Viscoelastoplastic Modeling of Compressional Behaviors of Kapok Fibrous Assembly, Textile Research Journal, 84(16), 1761–1775, 2014.https://doi.org/10.1177/0040517514528564

- Guo, X.+, Ouyang, W.+ and Xu, B.*, Assessing Cotton Maturity Using Distributional Parameters of Fiber Cross-section

Measurements, Textile Research Journal, 84(15), 1666–1676, 2014.

https://doi.org/10.1177/0040517514527375 - Yan, J+., Wang, F. and Xu, B.*, Compressional Resilience of Kapok Fibrous Assemblies, Textile Research Journal, 84(13), 1441–1450, 2014. https://doi.org/10.1177/0040517514523175

- Zhang, X., Wang, R.W.*, Wu, H. and Xu, B., Automated Measurements of Fiber Diameters in Melt-blown Nonwovens, Journal of Industrial Textiles, 43(4), 593–605, 2014. https://doi.org/10.1177/1528083712471696

- Lee, J., Freeland-Graves, J.H.*, Pepper, R., Yao, M.+ and Xu, B., Predictive Equations for Central Obesity via Anthropometrics, Stereovision Imaging, and MRI in Adults, Obesity, 22(3), 852–862, 2014. https://doi.org/10.1002/oby.20489

- Yao, M+., Zhao, Z.+ and Xu, B.*, Geometric Calibration of Line-scan Camera, Journal of Electronic Imaging, 23(1), 013028 (8pp), 2014. https://doi.org/10.1117/1.JEI.23.1.013028

- Wang, R.*, Xu, B. and Li, C., Accurate Fiber Orientation Measurements in Nonwovens Using Multi-focus Image Fusion Technique, Textile Research Journal, 84(2), 115-124, 2014. https://doi.org/10.1177/0040517513490056

- Ouyang, W.+, Wang, R. and Xu, B.*, Fabric Pilling Measurement Using 3D Images, Journal of Electronic Imaging, 22(4), 043031(9pp), 2013. https://doi.org/10.1117/1.JEI.22.4.043031

- Yan, J.+, Villarreal, N.+, and Xu, B.*, Characterization of Degradation of Cotton Cellulosic Fibers through Near Infrared Spectroscopy, Journal of Polymers and Environment, 21(4), 902-909, 2013. https://doi.org/10.1007/s10924-013-0605-z

- Ouyang, W.+ and Xu, B.*, Pavement Cracking Measurement Using 3D Laserscan Images, Measurement Science and Technology,24(10), 105204 (9pp),2013. https://doi.org/10.1088/0957-0233/24/10/105204

- Yan, J.+, Villarreal, N.+, Jay, C.K. and Xu, B.*, Evaluation of Color Change of the Curtain Dress, AATCC Review, 13(6), 37-43, 2013.

- Guo, X.+, Ouyang, W.+ and Xu, B.*, Shape Recognition of Profiled Fibers Using Triangle-Area Representation, Measurement Science and Technology, 24(9), 095401(10pp), 2013. https://doi.org/10.1088/0957-0233/24/9/095401

- Wang, F.*, Gu, F., and Xu, B., Elastic Strain of PTT/PET Self-Crimping Fibers, Journal of Engineered Fibers and Fabrics, 8(2), 50-55, 2013.

- Yan, J.+, Wang, F. and Xu, B.*, Compressibility of Kapok Fibrous Assemblies, Textile Res. J., 83(6), 1020-1029, 2013. https://doi.org/10.1177/0040517512460297

- Pepper, M. R., Freeland-Graves, J.H.*, Yu, W.+, Stanforth, P. R. and Xu, B., Evaluation of adult body adiposity, size, and shape by stereovision imaging, Journal of Testing and Evaluation, 41(1), 131-140, 2013. https://doi.org/10.1520/JTE20120169

- Yao, L., Wan, Y.+, Yao, M.+ and Xu, B.*, Detecting Fine Scratches on Smooth Surfaces with Multiscale Wavelet Representation, Measurement Science and Technology, 23(8), 085603(11pp), 2012. https://doi.org/10.1088/0957-0233/23/8/085603

- Bel, P.*+, Xu, B. and Boykin, D., Automatic Detection of Seed Coat Fragments in Cotton Fabrics, Textile Res. J., 82(16), 1711-1719, 2012. https://doi.org/10.1177/0040517511407370

- Wang, R.W.*, Tang, L.P., Zeng P.F. and Xu, B.*, Characterizing Profiled Fibers by Multi-scale Shape Representations, Journal of Testing and Evaluation, 40(3), 435-439, 2012. https://doi.org/10.1520/JTE104253

- Wan, Y.+, Yao, L. and Xu, B.*, Automatic Segmentation of Fiber Cross Sections by Dual Thresholding, Journal of Engineered Fibers and Fabrics, 7(1), 114-120, 2012.

- Wang, R.*, Xu, B., Zeng, P. and Zhang, X., Multi-focus Images Fusion for Enhancing Fiber Microscopic Images, Textile Res. J., 82(4), 352-361, 2012. https://doi.org/10.1177/0040517511407377

- Xu, B.*, Yu, W.+ and Wang, R.W., Stereovision for 3D Measurements of Fabric Pilling, Textile Res. J., 81(20), 2168–2179, 2011. https://doi.org/10.1177/0040517511418564

- Bel, P. D.*+, and Xu, B., Measurements of Seed Coat Fragments in Cotton Fibers and Fabrics, Textile Res. J., 81(19), 1983 -1994, 2011. https://doi.org/10.1177/0040517511407370

- Yao, X.+, Yao, M.+ and Xu, B.*, Automated Measurements of Road Cracks Using Line-scan Imaging, Journal of Testing and Evaluation, 39(4), 621-629, 2011. https://doi.org/10.1520/JTE103331

- Bel, P. D. +*, Xu, B. and Yao X.+, White Speck Potential for Mechanically Harvested Cottons, AATCC Review, 11(4), 59-65, 2011.

- Luo, J.+, Li, J., Wang, F.* and Xu, B., Elasticity of Woven Fabrics Made of PTT /PET Bicomponent Filaments, Textile Res. J., 81(8), 865–870, 2011. https://doi.org/10.1177/0040517510391700

- Sun, J.+, Yao, M.+, Bel, P.+ and Xu, B.*, Fabric Wrinkle Characterization and Classification Using Modified Wavelet Coefficients and Support-Vector-Machine Classifiers, Textile Res. J., 81(9), 902–913, 2011. https://doi.org/10.1177/0040517510391702

- Luo, J.+, Wang, F.* and Xu, B., Factors Affecting Crimp Configuration of PTT/PET Bicomponent Filaments, Textile Res. J., 81(5), 538-544, 2011. https://doi.org/10.1177/0040517510383616

- Shi, M., Fu, R., Guo, Y., Bai, S. and Xu, B.*, Fabric Defect Detection Using Local Contrast Deviation Feature Extraction, Multimedia Tools and Applications, 52(2), 147–157, 2011. https://doi.org/10.1007/s11042-010-0472-8

- Pepper, R., Freeland-Graves, J.*, Yu, W. +, Stanforth, P.R. and Xu, B., Evaluation of a Rotary Body Scanner for Measuring Body Volume and Fat, Journal of Testing and Evaluation, 39(1), 82-87, 2011. https://doi.org/10.1520/JTE102871

- Pepper, R., Freeland-Graves, J.*, Yu, W.+, Stanforth, P.R., Cahill, J., Mahometa, M. and Xu, B., Validation of A 3D Laser Body Scanner for Assessment of Waist and Hip Circumference, Journal of American College of Nutrition, 29(3), 179-188, 2010. https://doi.org/10.1080/07315724.2010.10719832

- Hu, X.+* and Xu, B., Reconstruction of Individualized Dress Forms Using Parameterized Silhouettes, International Journal of Clothing Science and Technology, 22(2/3), 114-126, 2010. https://doi.org/10.1108/09556221011018603

- Bel, P.+ and Xu, B.*, Fiber Longitudinal Measurements for Predicting White-Speck Levels of Dyed Cotton Fabrics, Textile Res. J., 80(11), 1047-1055, 2010. https://doi.org/10.1177/0040517509352516

- Wan, Y.+, Yao, Li, Zeng, P. and Xu, B.*, Shaped Fiber Identification Using A Distance-Based Skeletonization Algorithm, Textile Res. J., 80(10), 958-968, 2010. https://doi.org/10.1177/0040517509348329

- Li, Q.+, Yao, M.+, Yao, X+. and Xu, B.*, A Real-time 3D Scanning System for Pavement Distortion Inspection, Measurement Science and Technology, 21(1), 015702 (8pp), 2010. https://doi.org/10.1088/0957-0233/21/1/015702

- Xu, W.+*, Zhou, F., Ouyang, C., Ye, W., Yao, M., and Xu, B., Mechanical Properties of Small Diameter Polyurethane Vascular Grafts Reinforced by Weft Knitted Tubular Fabric, Journal of Biomedical Materials Research Part A, 92A(1), 1-8, 2010. https://doi.org/10.1002/jbm.a.32333 (IF=3.221)

- Yu, W+. and Xu, B.*, A Portable Stereo Vision System for Whole Body Surface Imaging, Image and Vision Computing, 28(4), 605-613, 2010. https://doi.org/10.1016/j.imavis.2009.09.015

- Wan, Y.+, Yao, Li, Xu, B.*, and Wu, X.Y., Separation of Clustered Fibers in Cross-sectional Images Using Image Set Theory, Textile Res. J., 79(18), 1658–1663, 2009. https://doi.org/10.1177/0040517509105697

- Wang, R., Wu, X.Y., Gao, Y.Y., Wang, S.Y.*, Xu, B., Automatic Identification of Ramie and Cotton Fibers Using Characteristics in Longitudinal View: Part II, Fiber Identification, Textile Res. J., 79(17), 1547-1556, 2009. https://doi.org/10.1177/0040517508089755

- 94.Xu, B.*, Yu, W.+, Yao, M.+, Pepper, R. and Freeland-Graves, J., 3-D Surface Imaging System for Assessing Human Obesity, Optical Engineering, 48(10), 107204 (11pp), 2009. https://doi.org/10.1117/12.824502

- Wang, R., Wu, X.Y., Gao, Y.Y., Wang, S.Y.*, Xu, B., Automatic Identification of Ramie and Cotton Fibers Using Characteristics in Longitudinal View, Part I: Locating Capture of Fiber Images, Textile Res. J., 79(14), 1251-1259, 2009. https://doi.org/10.1177/0040517509102723

- Xu, B.* and Bel, P.+, Evaluating Color Alterations of Fabrics, AATCC Review, 9(10), 37-42, 2009.

- 97.Xu, B.*, Yao, X.+, Bel, P.+, Hequet, E. and Wyatt, B., High Volume Measurements of Cotton Maturity by a Customized Microscopic System, Textile Res. J., 79(10), 937-946, 2009. https://doi.org/10.1177/0040517508095591

- Zhong, Y+. and Xu, B.*, 3-D Garment Dressing Simulation, Textile Res. J., 79(9), 792–803, 2009. https://doi.org/10.1177/0040517508090779

- Yu, W.+ and Xu, B.*, A Sub-pixel Stereo Matching Algorithm and Its Applications in Fabric Imaging, Machine Vision and Applications, 20(4), 261–270, 2009. https://doi.org/10.1007/s00138-007-0121-z

- 100.Yu, W.+, Yao, M.+ and Xu, B.*, 3-D Surface Reconstruction and Evaluation of Wrinkled Fabrics by Stereo Imaging, Textile Res. J., 79(1), 36–46, 2009. https://doi.org/10.1177/0040517508090497

- Shi, M., Jiang, S., Wang, H., and Xu, B.*, A Simplified Pulse-Coupled Neural Network for Adaptive Segmentation of Fabric Defects, Machine Vision and Applications, 20(2), 131–138, 2009. https://doi.org/10.1007/s00138-007-0113-z

- Yu, W.+ and Xu, B.*, Surface Reconstruction from Two-View Body Scanner Data, Textile Res. J., 78(5), 457-466, 2008. https://doi.org/10.1177/0040517507087853

- Xu, W.+*, Xu, B., Li, W. and Cui, W., Snippet Counting for Cotton Length Distribution Measurement Using Image Analysis, Textile Res. J., 78(4), 336–341, 2008. DOI: 10.1177/0040517508090478

- Yao, M.+, Yu, W.+, Xu., W. + and Xu, B.*, Evaluating Fabric Fuzziness Using Laser Range Sensing, Optical Engineering, 47(1), 013603(10pp), 2008. https://doi.org/10.1117/1.2834715

- Yao, M.+ and Xu, B.*, Evaluating Wrinkles on Laminated Plastic Sheets Using 3-D Laser Scanning, Measurement Science and Technology, 18(10), 3724-3730, 2007. https://doi.org/10.1088/0957-0233/18/12/007

- Zhong, Y.+ and Xu, B.*, A Physically Based Method for Triangulated Surface Flattening, Computer-Aided Design,38(10),1062-1073, 2006. https://doi.org/10.1016/j.cad.2006.05.002

- Bel, P. D.*+, and Xu, B., Image Analysis Measurements of White Specks on U.S. Extreme Varieties of Cotton. Textile Res. J., 76(7), 525-533, 2006. https://doi.org/10.1177/0040517506062633

- Huang, Y.+ and Xu, B.*, Automatic Inspection of Pavement Cracking Distress, Journal of Electronic Imaging, 15(1), 013017 (6pp), 2006. https://doi.org/10.1117/1.2177650

- Zhong, Y.+ and Xu, B.*, Automatic Segmentation and Measurement of Scanned Human Body, International Journal of Clothing Science and Technology, 18(1), 19-30, 2006. https://doi.org/10.1108/09556220610637486

- Kim, S.C.+, Hong, K.H., Kang, T.J. and Xu, B.*, Image Analysis for Quantifying Marquisette Damage in Home Laundering, Textile Res. J., 75(6), 474-479, 2005. https://doi.org/10.1177/0040517505053868

- Wang, F.*, Xu, G. and Xu, B., Prediction of the Shearing Rigidity of Woven Fabrics, Textile Res. J., Textile Res. J., 75(1), 30-34, 2005. https://doi.org/10.1177/004051750507500106

- Xu, B.* and Huang, Y.+, Image Analysis for Cotton Fibers, Part II: Cross-Sectional Measurement, Textile Res. J., 74(5), 409-416, 2004. https://doi.org/10.1177/004051750407400507

- Zhong, Y.+ and Xu, B.*, 3D Garment Wrapping Simulation Using Adaptive Force Fields, AATCC Review, 4(5), 17-20, 2004.

- Xu, B.* and Huang, Y.+, 3D Technology for Apparel Mass Customization, Part I: Rotary Body Scanning, Journal of Textile Institute, 94(1), 72-80, 2003. https://doi.org/10.1080/00405000308630595

- Xu, B.*, Yu, W.+, and Chen, T.+, 3D Technology for Apparel Mass Customization, Part II: Human Body Modeling from Unorganized Range Data, Journal of Textile Institute, 94(1), 81-91, 2003. https://doi.org/10.1080/00405000308630596

- Xu, B.* and Zhong, Y.+, 3D Technology for Apparel Mass Customization, Part III: Visualization of 3D Garments, Journal of Textile Institute, 94(1), 92-102, 2003. https://doi.org/10.1080/00405000308630597

- Xu, B.* and Lin, S.+, Automatic Color Identification in Printed Fabric Images by A Fuzzy-Neural Network, AATCC Review, 2(9), 42-45, 2002.

- Xu, B.*, Huang, Y.+ and Yu, W.+, A 3D Body Scanning System for Apparel Mass Customization, Optical Engineering, 41(7), 1475-1479, 2002. https://doi.org/10.1117/1.1478700

- Huang, Y.+ and Xu, B.*, Image Analysis for Cotton Fibers, Part I: Longitudinal Measurement, Textile Res. J., 72(8), 713-720, 2002. https://doi.org/10.1177/004051750207200811

- Holden, J., Keyes, N., Winkle, K. and Xu, B.*, Verification Test on the “AutoRate” System for Fabric Smoothness Appearance Evaluation, AATCC Review, 2(12), 27-30, 2002.

- Xu, B.*, Lin, S.+, Dale, D.+ and Watson, M.D., Cotton Color Classification by Fuzzy Logic, Textile Res. J., 72(6), 504-509, 2002. https://doi.org/10.1177/004051750207200607

- Kimmel, L.*, Xu, B., et. al., Investigation of Naturally Colored Cotton for Specialty Textile Products, AATCC Review, 2(5), 25-29, 2002.

- Xu, B.*, Lin, S.+, and Jiang, N.+, Measurement of Yarn Densities in Fabrics Using Phase-Shifted Digital Moire, Optical Engineering, 40(8), 1476-1480, 2001. https://doi.org/10.1117/1.1370555

- Xu, B.*, Huang, Y.+ and Watson, M.D., Cotton Color Distributions in CIE L*a*b*, Textile Res. J., 71(11), 1010-1015, 2001. https://doi.org/10.1177/004051759806800505

- Lin, S.+ and Xu, B.*, Evaluating Fabric Fuzziness Using Wavelet Transform, Optical Engineering, 39(9), 2391-2397, 2000. https://doi.org/10.1117/1.1287448

- Xu, B.*, Su, J. +, Dale, D.+ and Watson, M.D., Cotton Color Grading by Neural Network, Textile Res. J., 70(5), 430-436, 2000. https://doi.org/10.1177/004051750007000508

- Xu, B.* and Sreenivasan, S.V., A 3-D Body Imaging and Measurement System for Apparel Customization, Journal of Textile Institute, 90(2), 104-120, 1999. https://doi.org/10.1080/00405009908690632

- Xu, B.*, Wang, S+. and Su, J.+, Fiber Image Analysis, Part III: Autonomous Separation of Fiber Cross Sections, Journal of Textile Institute, 90(3), 288-297, 1999.

- Su. J.+ and Xu, B.*, Fabric Wrinkle Evaluation Using Laser Triangulation and Neural Network Classifier, Optical Engineering, 38(10), 1688-1693, 1999. https://doi.org/10.1117/1.602220

- Xu, B.*, Fang, C.+ and Watson, M.D., Clustering Analysis for Cotton Trash Classification, Textile Res. J., 69(9), 656-662, 1999. https://doi.org/10.1177/004051759906900906

- Xu, B.*, Cuminato, D.F.+ Huang, R.+ and Keyes, N.M., Evaluation of Fabric Smoothness Appearance Using a Laser Profilometer, Textile Res. J., 68(12), 900-906, 1998. https://doi.org/10.1177/004051759806801204

- Xu, B.*, Fang, C.+ and Watson, M.D., Investigating New Factors in Cotton Color Grading, Textile Res. J.,68(11), 779-787, 1998. https://doi.org/10.1177/004051759806801101

- Xu, B.*, Fang, C.+, Huang, R.+ and Watson, M.D., Cotton Color Measurements by an Imaging Colorimeter, Textile Res. J., 68(5), 351-358, 1998. https://doi.org/10.1177/004051759806800505

- Xu, B.*, Instrumental Evaluation of Fabric Pilling, Journal of Textile Institute, 88(4), 488-500, 1997. https://doi.org/10.1080/00405000.1997.11090899

- Xu, B.*, Fang, C.+, Huang, R.+ and Watson, M.D., Chromatic Image Analysis for Cotton Trash and Color Measurement, Textile Res. J., 67(12), 881-890, 1997. https://doi.org/10.1177/004051759706701204

- Xu, B.* and Yu, L.+, Determining Fiber Orientation Distribution in Nonwovens with Hough Transform Techniques, Textile Res. J., 67(8),563-571, 1997. https://doi.org/10.1177/004051759706700803

- Xu, B., Quantifying Surface Roughness of Carpets by Fractal Dimension, Clothing and Textiles Research Journal, 15(3), 155-161, 1997. https://doi.org/10.1177/0887302X9701500304

- Xu, B.* and Ting, Y.L.+, Fiber-Image Analysis, Part I: Fiber-Image Enhancement, Journal of Textile Institute, 87(2), 274-283, 1996. https://doi.org/10.1080/00405009608659080

- Xu, B.* and Ting, Y.L.+, Fiber-Image Analysis, Part II: Measurement of General Geometric Properties of Fibers, Journal of Textile Institute, 87(2), 284-295, 1996. https://doi.org/10.1080/00405009608659081

- Xu, B., Identifying Fabric Structures with Fast Fourier Transform Techniques, Textile Res. J., 66(8), 496-506, 1996. https://doi.org/10.1177/004051759606600803

- Xu, B.* and Reed, J.A., Instrumental Evaluation of Stain Release in Fabrics, Journal of Textile Institute, 87(1), 203-211, 1996. https://doi.org/10.1080/00405009608659068

- Xu, B., An Overview of Applications of Image Analysis to Objective Evaluation of Fabric Appearance, Journal of American Association of Textile Chemists and Colorists, 28(5), 18-23, 1996.

- Xu, B.*, Measurement of Pore Characteristics in Nonwoven Fabrics Using Image Analysis, Clothing and Textiles Research Journal, 14(1), 81-88, 1996. https://doi.org/10.1177/0887302X9601400110

- Xu, B.* and Reed, J.A., Instrumental Evaluation of Fabric Wrinkle Recovery, Journal of Textile Institute, 86(1), 129-135, 1995. https://doi.org/10.1080/00405009508631316

- Xu, B.* and Ting, Y.L.+, Measurement of Structural Characteristics of Fiber Segments in Nonwoven Fabrics, Textile Res. J., 65(1), 41-48, 1995. https://doi.org/10.1177/004051759506500106

- Xu, B., Assessing Carpet Appearance Retention by Image Analysis, Textile Res. J., 64(12), 697-709, 1994. https://doi.org/10.1177/004051759406401201

- Xu, B. and Pourdeyhimi, B.*, Evaluating Maturity of Cotton Fibers Using Image Analysis: Definition and Algorithm, Textile Res. J., 64(6), 330-335, 1994. https://doi.org/10.1177/004051759406400604

- Pourdeyhimi, B.* and Xu, B., Evaluating Carpet Appearance Loss: Pile Lay Orientation, Textile Res. J., 64(3), 130-135, 1994. https://doi.org/10.1177/004051759406400302

- Pourdeyhimi, B.*, Xu, B. and Wehrle, L., Evaluating Carpet Appearance Loss: Periodicity and Tuft Placement, Textile Res. J., 64(1), 21-32, 1994. https://doi.org/10.1177/004051759406400103

- Pourdeyhimi, B.* and Xu, B., Pore Characterization in Nonwoven Fabrics: Shape Consideration, Journal of Engineered Fibers and Fabrics (in lieu of International Nonwoven Journal), 6, 26-30, 1994.

- Xu, B., Pourdeyhimi, B.* and Sobus,J., Fiber Cross-Sectional Shape Analysis Using Imaging Techniques, Textile Res. J., 63(12), 717-730, 1993. https://doi.org/10.1177/004051759306301204

- Pourdeyhimi, B.*, Sobus, J. and Xu, B., Evaluating Carpet Appearance Loss: Surface Intensity and Roughness, Textile Res. J., 63(9), 523-535, 1993. https://doi.org/10.1177/004051759306300904

- Pourdeyhimi, B.* and Xu, B., Pore Size Characterization in Nonwoven Fabrics, Journal of Engineered Fibers and Fabrics (in lieu of International Nonwoven Journal), 5, 20-27, 1993.

- Xu, B., Pourdeyhimi, B.* and Sobus, J., Characterization of Fiber Crimp by Image Analysis: Definition, Algorithms and Techniques, Textile Res. J., 62(2), 73-80, 1992. https://doi.org/10.1177/004051759206200203

- Sobus, J., Pourdeyhimi, B.*, Xu, B., Ulcay, Y., Evaluating Loss of Texture Definition in Carpets Using Mathematical Morphology: Covariance, Textile Res. J., 62(1), 26-39, 1992. https://doi.org/10.1177/004051759206200105